Graphite Parts for Monocrystalline Silicon Furnaces

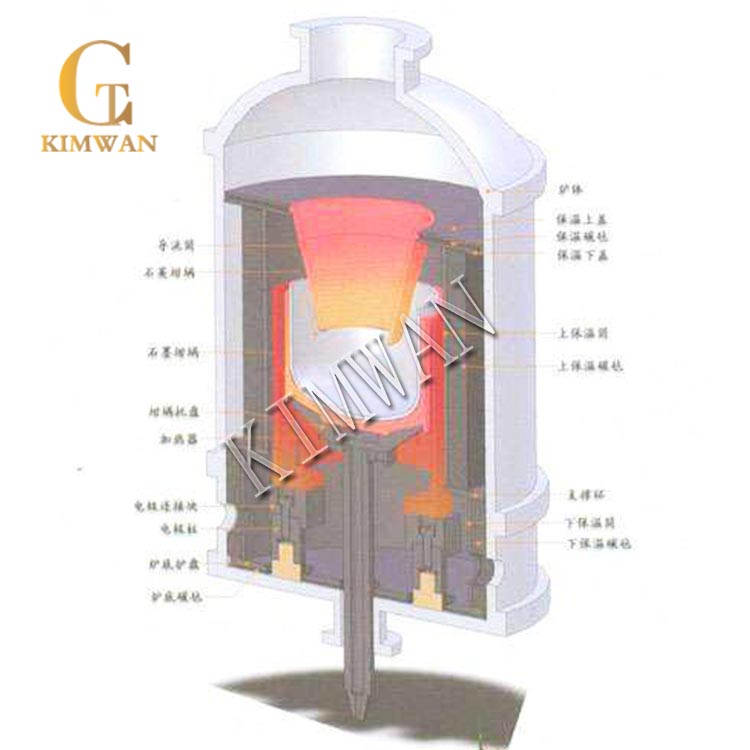

The graphite thermal field is the heart of a polycrystalline silicon ingot furnace, which inside contains graphite heaters, thermal insulation layers, tantalum and silicon materials. The structural design of the heating chamber of the polycrystalline silicon ingot furnace is very important during the production process of polysilicon. Graphite has a wide range of sources, can be processed into various shapes, and has a small thermal inertia, can be quickly heated, high temperature resistance, good thermal shock resistance, large radiation area, high heating efficiency, stable basic performance, etc. It becomes main raw material of the field because of those characters. Here is brief introduction of graphite thermal field system for straight-drawing single crystal furnace: The thermal system is used at high temperature for a long time, so the graphite material structure is required to be dense, strong, durable, small deformation, no void, no crack, and less metal impurities. The graphite material required for the thermal field is divided into three types: multi-purpose isostatic pressing, extrusion and molding.

Graphite thermal field

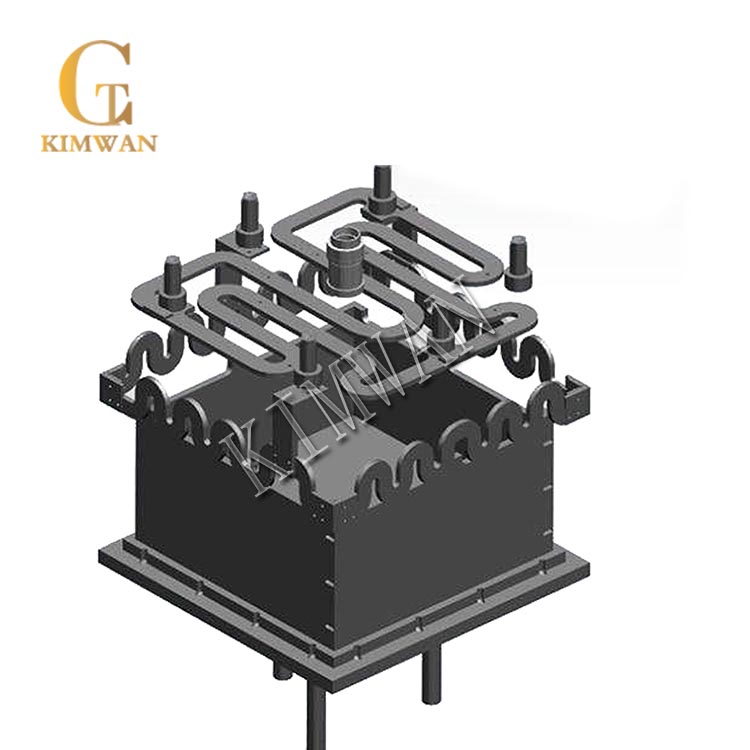

The graphite thermal field of most vacuum resistance furnaces consists of four main components:

Heater and its connecting parts

Thermal insulation (or reflective screen)

Graphite thermal field support component

Workpiece bearing hearth

The graphite thermal field is the core part of the vacuum resistance furnace, and its quality directly affects the performance of the furnace and its operating costs. The design of the graphite thermal field is varied, and the specific design is selected based on the specific analysis of the process.

Categorized by the shape, the graphite thermal field can be divided into square and circular, and the circular graphite thermal field occupies a high proportion in the vacuum furnace field.

In order to be easily installed and removed from the furnace, all graphite thermal fields are built into the form of modules.

Heater

Most high temperature vacuum furnaces use resistive heating. The material of the heater can be metal or graphite. The heater can be designed in a variety of forms as needed. The choice of heater material depends primarily on the operating temperature. For low operating temperatures, such as vacuum tempering furnaces, inexpensive nickel-chromium alloys can do the job. Molybdenum and graphite are currently the most popular materials for applications such as furnaces and brazing furnaces that require high temperatures for heat treatment. For many years, molybdenum metal has been used almost exclusively in vacuum heat treatment and brazing furnaces. There is also a common misconception that substances emitted from graphite materials react chemically with certain materials and contaminate the workpieces in the furnace.

Single crystal graphite thermal field

Early graphite heaters were limited to the kind of simple shapes, and the connections and electrical properties between the graphite components were not very stable.

With the improvement of graphite material properties and processing technology, more and more graphite heaters have been applied to heat treatment and brazing furnaces, which have exceeded the number of molybdenum heaters.

Polycrystalline graphite thermal field

The graphite furnace thermal field of the ingot furnace is mainly composed of three materials: special graphite is used for heaters, graphite electrodes, graphite crucibles, DS blocks, support rods, intake pipes and other components.