Magnet sintered graphite sagger processing device method

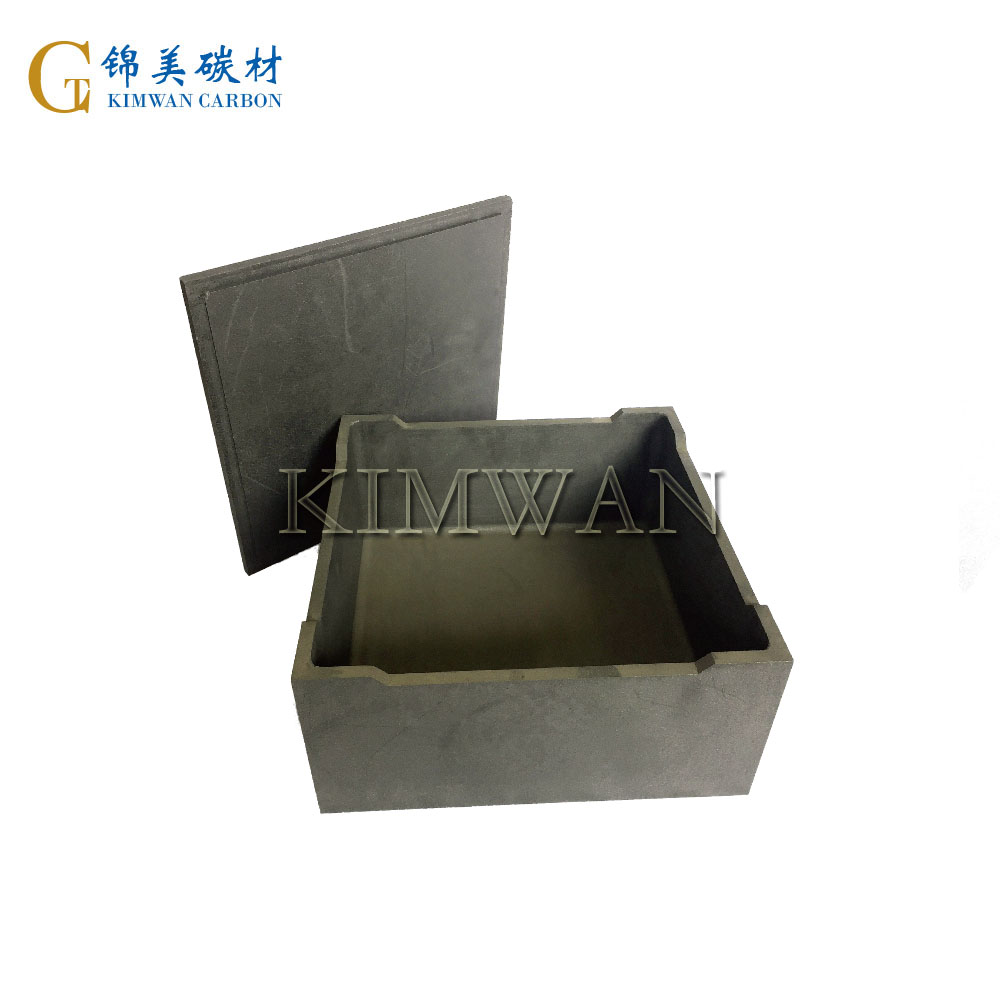

The first is the magnet sintered graphite sagger and processing device. The graphite sagger includes a frame surrounded by a plurality of side walls, a first bottom layer and a second bottom layer; the frame body and the first bottom layer enclose a cavity for placing the material to be sintered; the first bottom layer and The second bottom layer is arranged so that the two can be closely attached; the second bottom layer is arranged under the first bottom layer in a freely extractable manner; the first bottom layer is provided with a plurality of pores, and the second bottom layer is not provided with pores. The graphite sagger adopting the patented technology of the utility model can be tempered without changing the container after high-temperature sintering, and can realize rapid and uniform cooling.

Neodymium iron boron magnets are very important industrial raw materials, which can be used in the audio field, motor field, computer field, etc. The preparation process of NdFeB magnet includes sintering method and bonding method. It is generally believed that the performance of NdFeB magnets obtained by sintering method is more excellent. In order to further improve the performance of NdFeB magnets, the sintering process usually includes two processes: high temperature sintering and tempering treatment.

The sintering process of NdFeB magnets is usually carried out in a vacuum sintering furnace. The raw material of the neodymium iron boron magnet is placed in a graphite sagger, the graphite sagger is sealed, and then placed in a vacuum sintering furnace for sintering. The neodymium iron boron magnet blank obtained by isostatic pressing will release gas as the temperature rises during the high-temperature sintering process. This requires the graphite sagger to have better sealing properties to prevent the gas from overflowing from the graphite sagger from recurring. It oxidizes materials when entering the box.

After sintering is completed, the material needs to be tempered. Fast and uniform cooling is beneficial to obtain a magnet with good consistency and high performance. However, due to the good sealing performance of the traditional graphite sagger, it cannot meet the requirements of rapid and uniform cooling. Therefore, it is usually necessary to pour high-temperature materials into a perforated material box for rapid cooling. Therefore, the traditional sintering process has a long process flow and low operational safety. Therefore, there is an urgent need for a graphite sagger, which can be tempered without changing the container after high-temperature sintering, and can achieve rapid and uniform cooling.

The purpose of the present technology is to provide a magnet sintered graphite sagger, which can be tempered without changing the container after high-temperature sintering, and can achieve rapid and uniform cooling. Another object of the present technology is to provide a magnet processing device, which can shorten the process flow of the sintering process and significantly improve the operational safety. This technology adopts the following technical solutions to achieve the above objectives. The present technology provides a magnet sintered graphite sagger, which includes a frame surrounded by a plurality of side walls, a first bottom layer and a second bottom layer; the frame and the first magnet sintered graphite sagger are characterized in that: The graphite sagger includes a frame surrounded by a plurality of side walls, a first bottom layer and a second bottom layer; the frame body and the first bottom layer enclose a cavity for placing the material to be sintered; the first bottom layer and the second bottom layer The second bottom layer is arranged so that the two can be closely attached; the second bottom layer is arranged under the first bottom layer in a freely extractable manner; the first bottom layer is provided with a plurality of pores, and the second bottom layer is not provided with pores.