The advantages of graphite rods

Many people don’t know how to improve efficiency when using graphite saggers. The following editor will teach you some overlapping methods, which have three advantages:

The life span of the graphite rod has a lot to do with its degree of oxidation. In a normal temperature environment, graphite rods start to oxidize from more than 500 degrees Celsius, but the degree of oxidation is very small. As time changes and temperature rises, the degree of oxidation of graphite rods begins to increase.The impregnated graphite rods have better high temperature resistance than ordinary graphite rods. How to extend the service life of graphite rods? You can add nitrogen or ammonia for anaerobic protection, or apply some anti-oxidation coating on the graphite rod itself, which can play an ideal protective role;

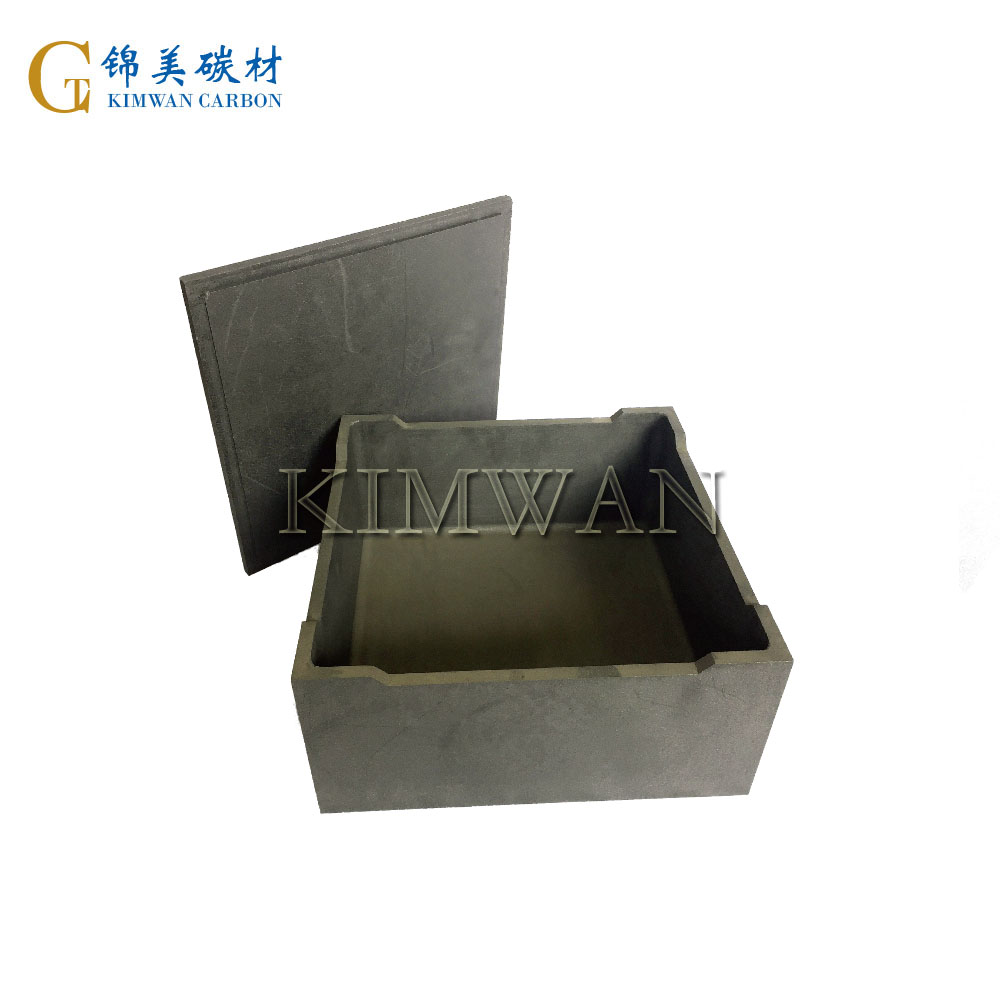

In the early and mid-Yuan Dynasty, the firing of Mangkou porcelain usually continued to use the ring-covering method, but at this time the support ring had been changed from the porcelain of the Song Dynasty to the muddy urn. The sagger is one of the kiln furniture. In the process of firing ceramics, in order to prevent gas and harmful substances from damaging and staining the green body and glaze, the ceramics and green bodies are fired in a container made of refractory materials, which is called a sagger , Also known as box. Using saggers to burn ceramics can not only increase the burning capacity, prevent the products from sticking, and increase the yield, but also have certain thermal conductivity and thermal stability to ensure the quality of ceramics. The shape of the sagger varies according to the shape of the utensil.

Mounting the blank is easier than the fifth generation.。 It can make full use of the high altitude in the kiln room to increase the burning capacity, which can save refractory materials and roasting costs. Because the defect of exposed tires is only in the center of the bowl or the center of the pan, it is more suitable than the unglazed sintering device.