HP Graphite Electrode For STEEL

Fine-grained and dense, isotropic high purity graphite has good machining performance, easy to form and modify. It will not deform when making thin and deep bone electrodes. Low density makes it not deform so that it is suitable for making tool electrode for large parts or mold processing, and be small in overall mass. Graphite is easy to process, and its processing efficiency is at least three times higher than that of copper. The discharge speed is also much faster than copper. As a high-efficiency, short delivery time mold, graphite is the trend of development.

Graphite Electrode

Advantages of Graphite

Design of Electrode

Can reduces the number of individual electrodes/ Can be made into combined electrode

Can save electrode fixture system and cost

Fabrication of Electrode

High speed milling is three times faster than copper rough machining

High speed milling and finishing is 5 times faster than copper

Good processability

Can achieve complex geometric modeling

Light Weight, Less than 1/4 of Copper Density

Good thermal stability (No deformation)

Can reduce the number of individual electrodes/ Can be made into combined electrode

No need to deburr

Easy electrode clamping

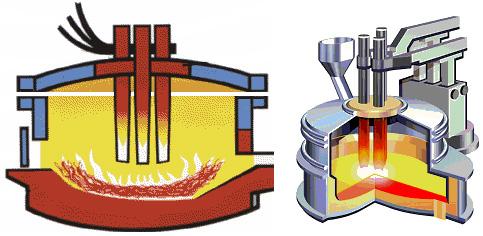

Electric Discharge Machining

Low electrode loss during roughing

High working removal rate

Can reduce the number of individual electrodes/ Can be made into combined electrode

No pollution to environment in electrolyte

Light weight, less than 1/4 of copper density

Excellent thermal stability, the electrode is not deformed

The use of fine-grain graphite electrodes can produce high-quality workpiece surfaces

Graphite Electrode

技术指标:Technical indicators:

高功率石墨电极技术指标:High power graphite electrode technical indicators:

指标Index |

单位unit |

公称直径 300-500mm Nominal Diameter |

|

电阻率Resistivity |

电极electrode |

μΩm |

7.0 |

接头connector |

6.5 |

||

抗折强度Flexural strength |

电极electrode |

MPa |

10.0 |

接头connector |

14.0 |

||

弹性模量Elastic Modulus |

电极electrode |

GPa |

12.0 |

接头connector |

16.0 |

||

灰分Ash |

电极electrode |

% |

0.3 |

接头connector |

|||

体积密度bulk density |

电极electrode |

g/cm3 |

1.64 |

接头connector |

1.72 |

||

热膨胀系数Thermal expansion coefficient |

电极electrode |

10-6 1/℃ |

2.4 |

接头connector |

2.2 |

允许电流:Allowable current

公称直径(mm)Nomical diameter(mm) |

允许电流(A)allowable current(A) |

300 |

13000-17400 |

350 |

17400-24000 |

400 |

21000-31000 |

450 |

25000-40000 |

500 |

30000-48000 |